This new technology is growing fast within the community of marine surveyors. The cost of acquiring these thermal imaging cameras is going down and the training costs are also getting more affordable. Thermal imaging technology allows seeing what the human eye can’t. A thermal imaging camera will allow you to see the thermal radiation coming from different materials or systems that may be potentially defective. When a system is overheating because of a problem – for instance, an electric control box in which a wire gets too much amperage or an electric motor that is not well maintained and therefore is overheating – it is then possible with this technology to detect the area of the system that does not operate well.

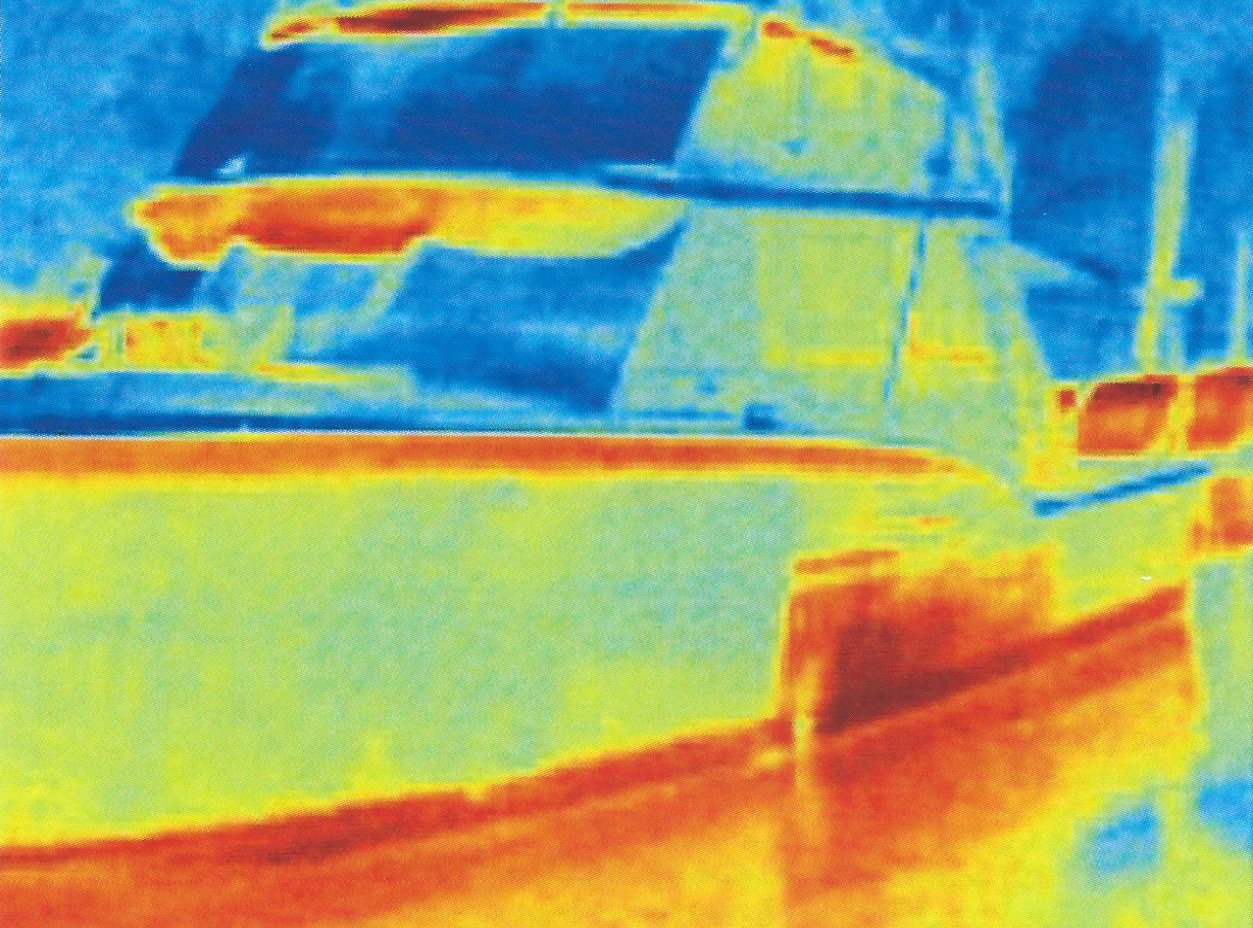

For the same reason, a delaminated area of a GRP hull that will absorb seawater will show a temperature that is different compared to the sound parts of the same hull. Under the effect of solar radiation, this GRP hull is going to heat and the humid areas of this hull will show a different temperature compared to the sound areas.

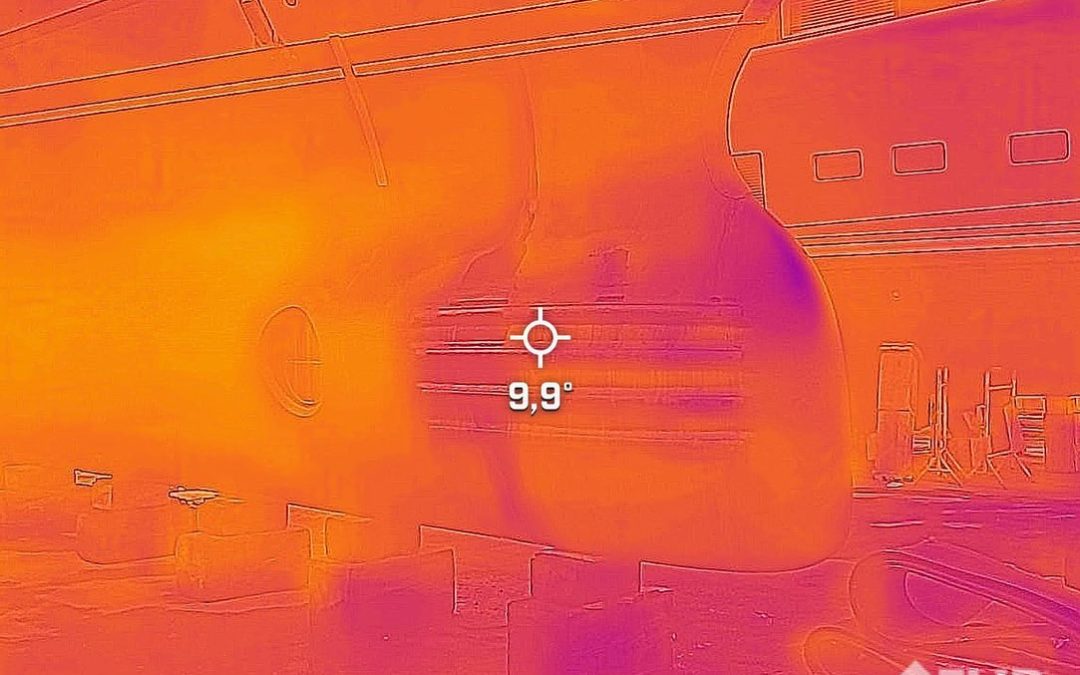

An image worth a thousand words!

This image clearly shows a hot area in the dead works of the hull. Is this area of the polyester sandwich hull damaged? Or maybe it is thermal radiation from the engine room… Beware!

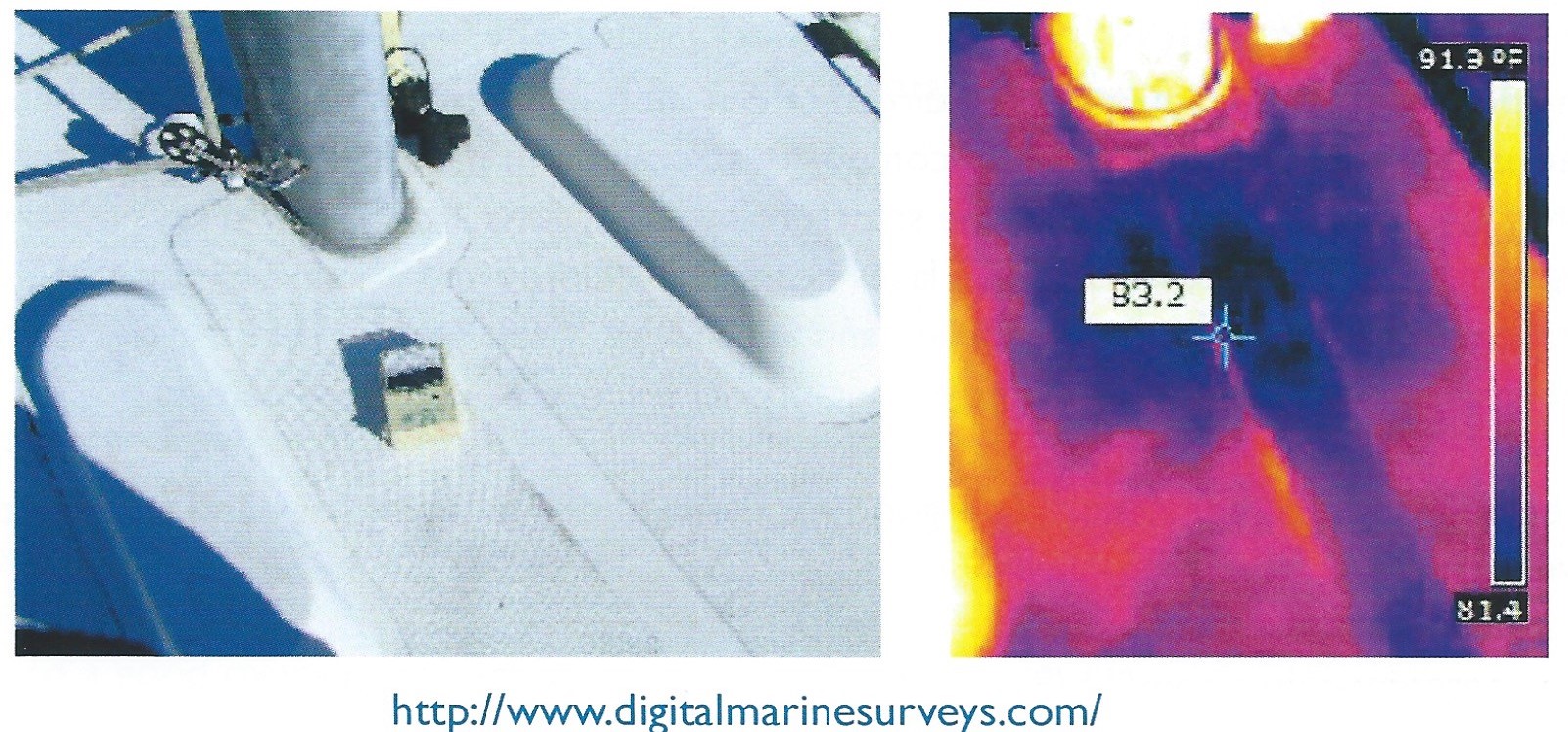

These two images show the deck of a sailboat built in sandwich balsa/polyester. The deck is delaminated in front of the mast and the dark zone shows it. The balsa core has absorbed humidity which is confirmed by the humidity tester and the thermal imaging camera.

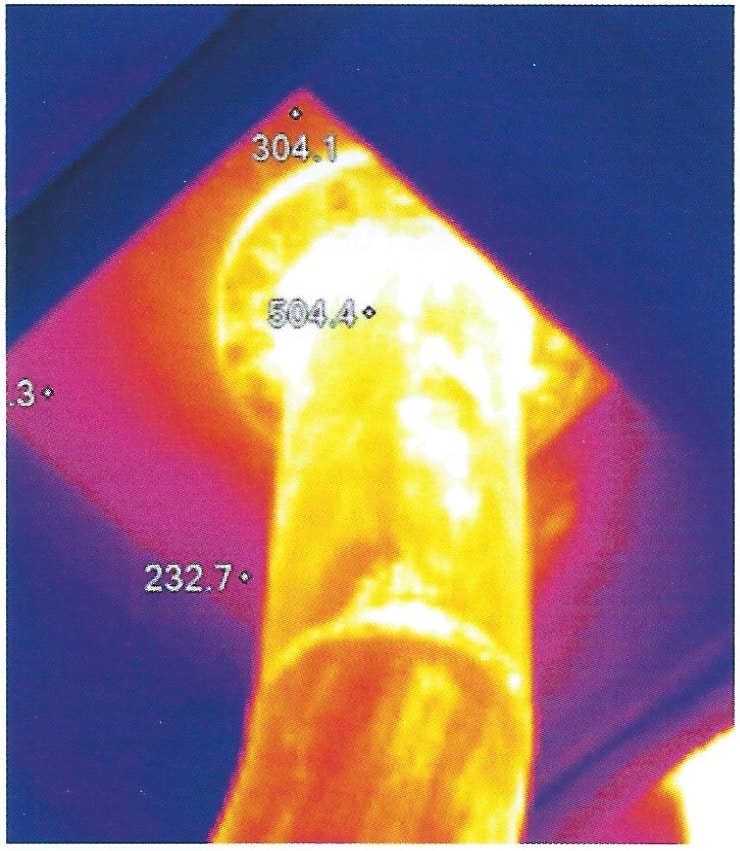

This technology of thermal imaging allows you to inspect engines, gear boxes, and electric systems. In other terms, wherever there is a temperature difference between a normal and a problematic situation, thermal imaging is an efficient tool for diagnosis. The picture above shows the reduction of the thickness of an exhaust pipe caused by corrosion. The upper part is corroded and overheats.